Hydraulic Weldless and Crimp Piping & Components

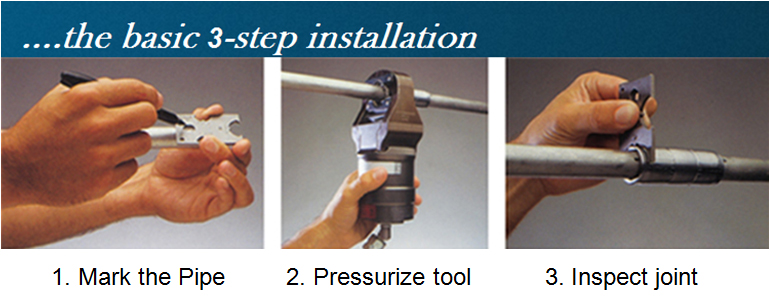

After cutting and preparing the pipe…

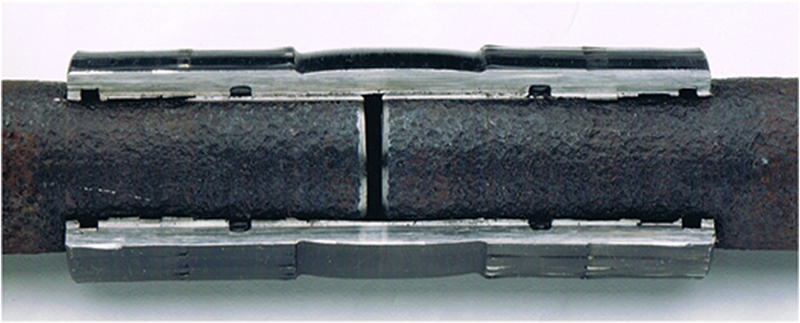

- Sample above : ¾” NPS pipe pitted due to years of exposure

- Performed 6,000 PSI (420 bar) hydrostatic proof test

- 1,000 Psi (70 bar) nitrogen leak test

- Zero leakage detected

PYPLOK TEST SUMMARY

| TEST | REQUIREMENTS | RESULTS |

| Gas Leak Test | Gn2 Nitrogen 1,000 PSI for 10 minutes | No leakage |

| Hydrostatic Burst | Based on 4 x Operating Pressure held for 5 minutes | No leakage |

| Hydrostatic Proof | Based on 1.5 x Operating Pressure held for 5 minutes | No leakage |

| Vibration Test | 20,000,000 cycles at displacement @ operating pressure | Passed |

| Impulse Test | 500,000 cycles @ 1.33 x Operating Pressure based on ISO/BS Impulse Cycle | Passed |

| Impulse/Flexure and Fatigue at Low Temperature | Simultaneous impulse and bending stress, 8 times during test of 10,000 cycles each under peak pressure and rated bending each fitting was subjected to -100 deg F for one hour utilizing liquid CO2. | No leakage |

| Tensile Test | Fitting was installed in tensile machine with cross head speed of 0.20 in/min and pulled until one side of pipe dismembered from the fitting/pipe joint | Exceeded Tensile Strength by a factor of 1.33 to 1.63 |

| Torsion Test | At various Torsion Angles and Ft-Lbs of Torque @4500 Psig (Gn2) and 6000 Psig (Hydraulic Fluid) | No Leakage |

| Heat Aging | Maintained at 400 deg F ± 5 deg F for 168 hours, Proof test @ 6000 Psig for 30 minutes | Passed |

PYPLOK Approvals and standards

- ISO 9001:2008 Certified

- ANSI/ASME B31.1 and B31.3

- ANSI/ASME B31.4

- ANSI/ASME B31.8

- CRN – Canadian Registration No. 0A12153.5

- TSSA – Technical Standards and Safety Authority

- ABSA – Alberta Boilers Safety Association

- API 6FB Third Edition Fire Test for end connection fittings

- ISO 19921 Fire Test, Fire Resistance of Metallic Pipe Components with Resilient and Elastomeric Seals

- NAVSEA – United States Naval Sea Systems Command

- US Military Navy Shock Test MIL-S-901D

- ANZAC – Australian, New Zealand Navy

- US Coast Guard

- Canadian Coast Guard

- ABS – American Bureau of Shipping, Certificate 02-HS269945D/2-PDA

- DNV – Det Norske Veritas, Certificate P-13306

Tube-mac successfully achieved type approvals from IACS (International association of classification societies) Members…

- LR – Lloyds Registry

- DNV – Det Norske Veritas

- ABS – American Bureau of Shipping

- CCS – China Classification Socie

Benefits of PYPLOK WELDLESS FITTINGS versus welded FITTINGS

- No special skilled labour required vs. qualified welder.

- Actual swaging time is measured in “seconds” vs. “hours” for a welded joint.

- No special hot work permits

- No fire watch personnel required.

- No leaks as a result of stress fatigue cracks as seen in welds.

- No off loading or purging of fluids and gases.

- No cost to x-ray welds.

- No cost to re-work welds.

- No acid flush chemicals and neutralizers required.

- No added cost or environmental issues to dispose of chemical waste.

- SAFE cold work fitting technology.

- SAFE and easy to install in tight confined places.

- SAFE permanent, tamper proof connection.

Benefits of PYPLOK FITTINGS versus other connections

- One piece fitting versus multi-piece bite-type fitting.

- No threads or nuts that loosen over time.

- No need to rely on the strength of the installer.

- SAFE pre-engineered swage tool assures repeatable, leak-free and reliable connections.

- SAFE for maintenance repairs in hazardous areas.

- Can be installed on a wider range of pipe/tube wall thicknesses.

- SAFE for high pressure applications.

- Easy to install in tight tube runs side-by-side.

- Through bore design allows for zero clearance installation.

- No other sealants or lubricants required.

Pyplok applications

| CNG – Compressed Natural Gas | Hydraulic Oil |

| Paint and Sealer Lines | Low Temperature Steam |

| Condensate Piping | LPG – Liquefied Petroleum Gas |

| Deluge Systems | Lubrication and Grease |

| Down Well Coiled Tubing | Natural Gas |

| Drains and Plumbing Vents | Waste Water |

| Ethylene Glycol/Water | RAD Waste Systems |

| Fuel Oil and Fuel Gas | Solvents and Water Based Paints |

| Gases – Nitrogen, Air, Helium | Subsea Piping |

| Heating Coil | Steam Tracer Lines |

| High Pressure Water Mist/Fog – Fire Suppression Systems | Plant Instrumentation and Utility Air |

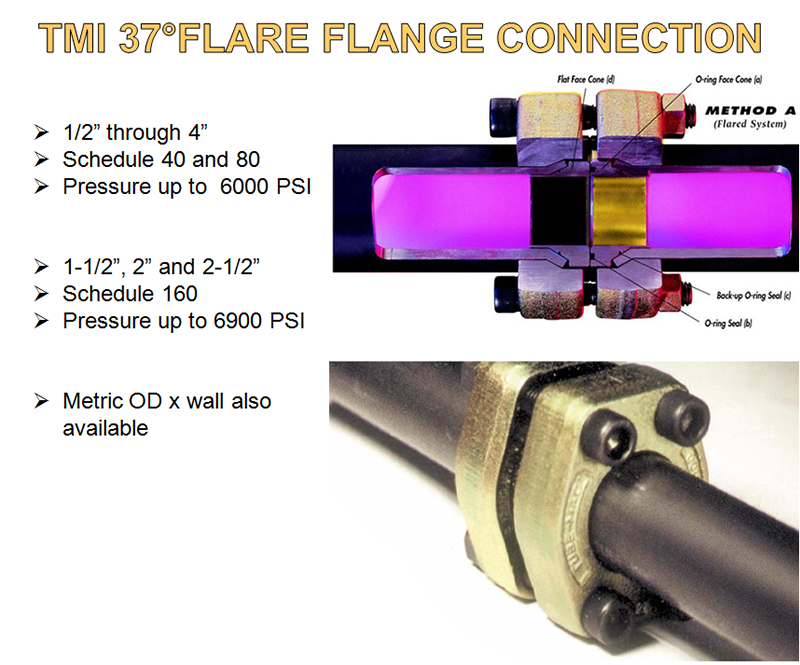

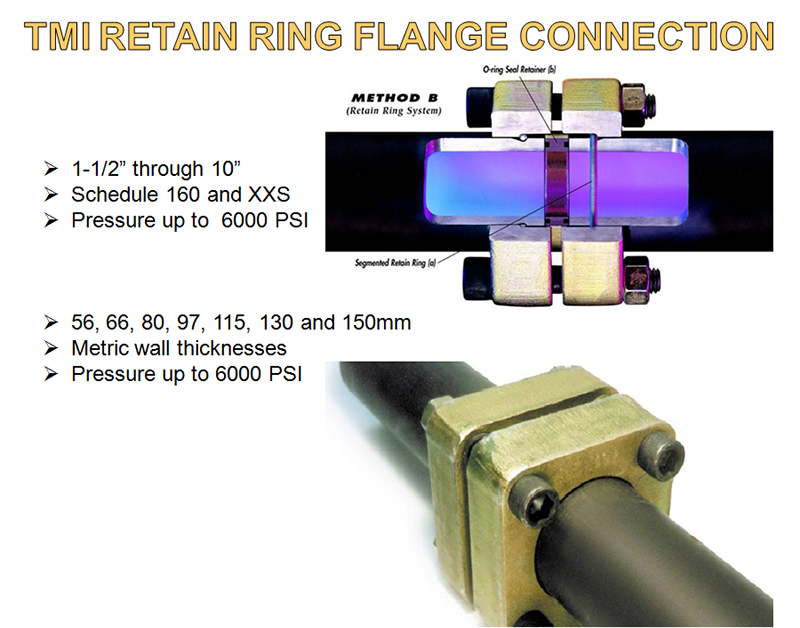

Benefits of a TMI non-welded system versus welded system

- No special skilled labour required vs. qualified welder.

- Actual flaring time is measured in “seconds” vs. “hours” for a welded joint.

- No special hot work permits

- No fire watch personnel required.

- No leaks as a result of stress fatigue cracks as seen in welds.

- No cost to x-ray welds.

- No cost to rework welds.

- No acid flush chemicals and neutralizers required.

- No added cost or environmental issues to dispose of chemical wastes.

- SAFE cold work technology.

- Tube-Mac Project Coordinators develop and cost up BOM.

- Field bend and fabrication – reduces engineering design time.

- On-site container – reduces warehouse and inventory costs.